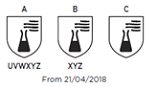

CE CATEGORY

European Directive 89/686/EEC

CATEGORY I Minor risks.

CATEGORY II Reversible risks (injury), certified compliant by a notified body.

CATEGORY III Irreversible risks (corrosion), certified compliant and tested by a notified body whose number is specified.

*The European Directive 89/686/EEC on PPE is in process of being superseded by a new PPE Regulation (EU) 2016/425. The new Regulation, that introduces revisions in several PPE standards such as EN 388 and EN 374, was published in the Official Journal of the European Union on 31st March 2016 and will be applied from 21st April 2018. Our new and existing gloves may not be certified according to this new Regulation until 21st April 2018. The existing certificates according to the Directive will remain valid until 21st April 2023.

EN 420

General requirements and test methods

- • Technical information*

- • Glove markings

- • Sizes

- • Level of dexterity (1 to 5)

- • Innocuousness of the glove

* Printed on the packaging or on the user instruction of SHOWA gloves.

EN 388: 2016

Mechanical risks

- a) ABRASION RESISTANCE (0-4)

- Number of cycles required to abrade a hole using abrasive paper in a circular sample of glove material under constant pressure and motion.

- b) BLADE CUT RESISTANCE BY COUP TEST (0-5)

- Number of cycles required to cut a sample using a stainless steel circular blade under constant speed and low force of 5 newtons (approx. 510g). For materials that dull the blade, after a certain number of cycles without cut through, the ISO 13997 test is performed and becomes the reference cut resistance value.

- c) TEAR RESISTANCE (0-4)

- Force required to propagate a tear in a rectangular sample of a glove with a starting incision, to a maximum force of 75N (approx. 7,6kg).

- d) PUNCTURE RESISTANCE (0-4)

-

Force required to puncture the sample with a standard size steel point at a constant speed of 10 cm/min.

Level of protection 1 2 3 4 5 Abrasion resistance (number of cycles) >100 ≥500 ≥2000 ≥8000 - Blade cut resistance by Coup test (index) >1,2 ≥2,5 ≥5 ≥10 ≥20 Tear resistance (force in newtons) >10 ≥25 ≥50 ≥75 - Puncture resistance (force in newtons) >20 ≥60 ≥100 ≥150 - - e) BLADE CUT RESISTANCE BY ISO TEST (A-F)

-

Force in newtons (N) required to cut through a sample using a rectangular blade in a specified cut test machine such as Tomodynamometer (TDM). This test is optional unless the blade in Coup test becomes dull, whereupon it becomes the reference for cut resistance. A letter value is assigned as follows:

Level of protection A B C D E F Force in newtons >2 ≥5 ≥10 ≥15 ≥22 ≥30 Cut resistance LOW MEDIUM HIGH - f) IMPACT RESISTANCE (P)

- For protective gloves claiming impact resistance. Measures dissipation of force by the area of protection upon an impact of a domed anvil at an impact energy of 5 joules. Testing is carried out in accordance with the impact protection test for motorcycle protective gloves of EN 13594:2015 standard. A letter “P” is added on successful pass, while a fail remains unmarked.

Level X can also be applied for a – f above, which means “not tested”.

*Revision of EN 388: 2003

The EN 388 standard underwent revision in 2016. SHOWA gloves are in the process of being recertified by the notified bodies to conform to the revised standard. Currently reported ISO 13997 cut resistance values are indications until officially certified. In the meantime the existing certificates according to EN 388: 2003 remain valid.

EN ISO 374: 2016

The standard defines requirement the capability of gloves to protect the user against penetration, permeation and degradation by chemicals and microorganisms. It classifies three types of gloves by level of protection (A, B, and C).

EN 374-2: 2014

Penetration resistance

The gloves must pass the air leak and/or water leak test, and meet the defined AQL inspection level. In an air leak test the interior of glove is pressurized with air and the surface is checked for holes. In a water leak test the glove is filled with water, and checked for the appearance of water droplets on the outside surface after a defined time period.

AQL (accepted quality level) is a measure of quality assurance based on random sampling procedure according to ISO 2859-1 used by manufacturers for measuring the likelihood of pinhole defects in a batch of gloves. An AQL of 1,5 accepts the statistical probability that there are less than 1,5% of the gloves with defects in the batch.

| Performance level | Acceptable quality level unit | Inspection levels |

| Level 3 | < 0,65 | G1 |

| Level 2 | < 1,5 | G1 |

| Level 1 | < 4,0 | S4 |

EN 16523-1: 2015 (replaces EN 374-3)

Resistance to chemical permeation

Test method to measure the resistance of the PPE material to permeation by hazardous chemicals at molecular level and under continuous contact. The resulting value is the breakthrough time or the time needed by the hazardous liquid or gas to get in contact with the skin. The glove is classified in terms of breakthrough time performance level 1 to 6.

| Measured breakthrough time | Permeation performance index |

| > 10 | 1 |

| > 30 | 2 |

| > 60 | 3 |

| > 120 | 4 |

| > 240 | 5 |

| > 480 | 6 |

The standard defines a list of 18 chemicals. The minimum breakthrough time for a Type A glove is 30 mins (Level 2) for 6 chemicals, for a Type B it is 30 mins for at least 3 chemicals, and for Type C it is 10 mins (Level 1) for at least 1 chemical on the list.

| Type of gloves | Breakthrough time |

| A | ≥30 min for at least 6 chemicals |

| B | ≥30 min for at least 3 chemicals |

| C | ≥10 min for at least 1 chemical |

The ‘chemical resistant’ glove pictogram must be accompanied by code letters for the tested chemicals for Type A and Type B gloves. Type C marked gloves are without any code letter.

List of chemicals:

| Letter code | Chemical | CAS number | Class |

| A | Methanol | 67-56-1 | Primary alcohol |

| B | Acetone | 6764-1 | Ketone |

| C | Acetonitrile | 75-05-8 | Nitrile compound |

| D | Dichloromethane | 75-09-2 | Chlorinated hydrocarbon |

| E | Carbon disulphide | 75-15-0 | Organic compound containing sulphur |

| F | Toluene | 108-88-3 | Aromatic hydrocarbon |

| G | Diethylamine | 109-89-7 | Amine |

| H | Tetrahydrofurane | 109-99-9 | Heterocyclic ether |

| I | Ethyl acetate | 141-78-6 | Ester |

| J | n-Heptane | 142-85-2 | Saturated hydrocarbon |

| K | Caustic soda 40% | 1310-73-2 | Inorganic base |

| L | Sulphuric acid 96% | 7664-93-9 | Inorganic mineral acid |

| M | 65% Nitric acid | 7697-37-2 | Inorganic mineral acid, oxidizing |

| N | 99% Acetic acid | 64-19-7 | Organic acid |

| O | 25% Ammonium hydroxide | 1336-21-6 | Organic base |

| P | 30% Hydrogen peroxide | 7722-84-1 | Peroxide |

| S | 40% Hydrofluoric acid | 7664-39-3 | Inorganic mineral acid, contact poison |

| T | 37% Formaldehyde | 50-00-0 | Aldehyde |

EN 374-4: 2013

Resistance to chemical degradation

Degradation is the deleterious change in one or more properties of a protective glove material due to contact with a chemical. Indications of degradation can be delaminating, discoloration, hardening, softening, dimensional change, loss of tensile strength, etc. It is determined by measuring the percentage change in puncture resistance of the glove material after a continuous contact for 1 hour of the external surface with the challenge test chemical. The results of the degradation test must appear in the information leaflet for all three glove types.

EN 374-5: 2016

Protection against micro-organisms

Micro-organisms are defined by the standard as bacteria, fungi or viruses. To claim resistance to bacteria and fungi the glove must pass the penetration resistance test according to standard EN 374-2: 2014. If the glove passes ISO 16604: 2004 (method B) test it can claim resistance to viruses as well, and the term “VIRUS” will be added below the biohazard pictogram.

EN 511

Cold-related risks

Tested levels of glove performance in terms of the following risks:

- • Climatic or industrial cold transmitted by convection (0 to 4).

- • Climatic or industrial cold transmitted by contact (0 to 4).

- • Impermeability to water (0 or 1).

If the glove shows this symbol, it has achieved a performance index for (from left to right) climatic cold or industrial cold transmitted by convection, climatic cold or industrial cold transmitted by contact, impermeability to water.

“0” means that during the test level 1 was not reached.

“X” means that the test was not performed or not possible.